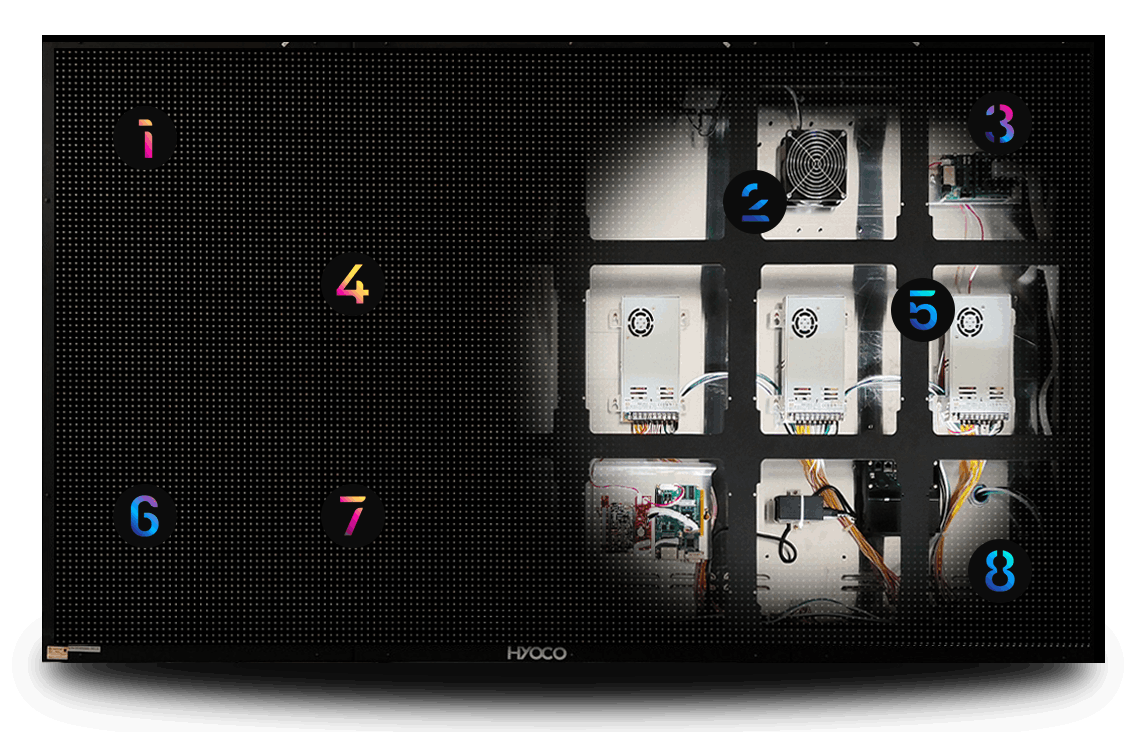

LED ANATOMY

LED Display stands out like landmark brilliantly and prominently, attracts attention with no equivalence.

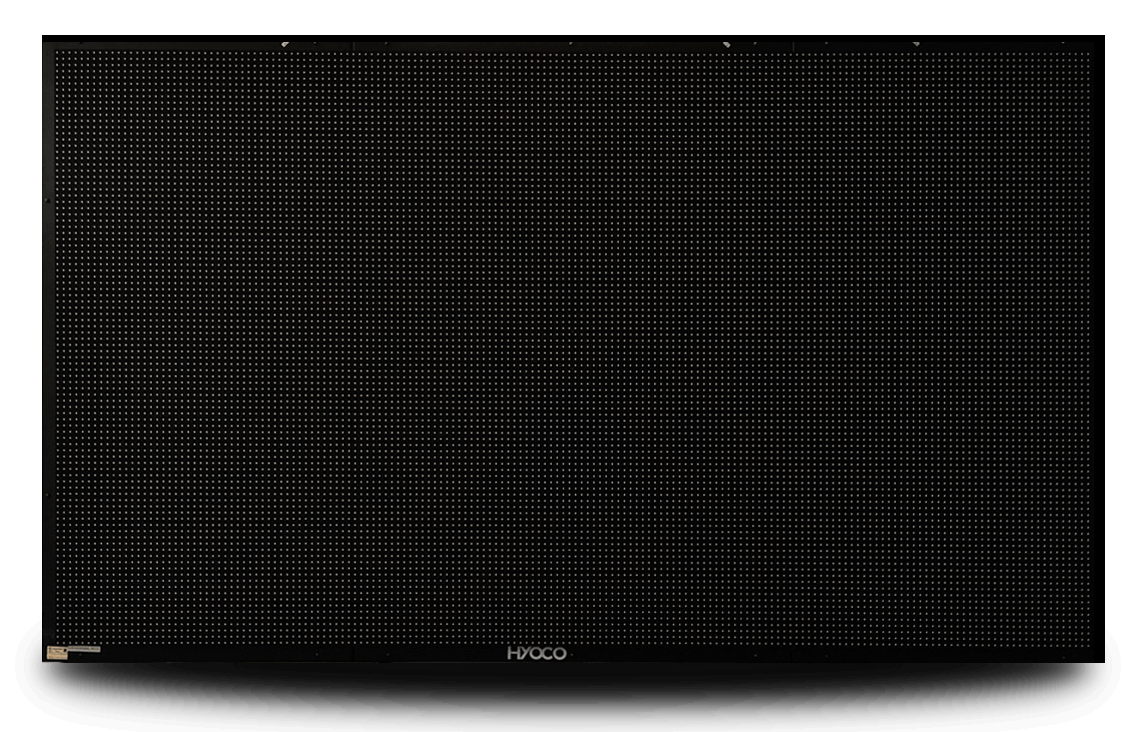

Front Panel

Depending on the size of the display, 3 opening mechanism options: Sliders, Metal Cables and Gas Shocks.

Cooling

Thermostatically controlled forced air ventilation with optional heater.

Exterior

Finishing with ultra high quality powder coating material made in the America from AKZO.

Pixel/Modules

Unique display modules with Electrostatic Discharge (ESD) protection and IL technology, made from materials by General Electric (GE). Optional Hyoco Removable Pixel (HRP) modules are also available.

Power

All PCB-Emperor/Genesis Series use high grade Power Supply with Auto Protection feature specifically made for Hyoco.

LEDs

Printed Circuit Board (PCB) based Emperor Series utilize Nichia diodes that are made in Japan. While the PCB-Genesis Series uses a mixture of Nichia and Everlight LEDs.

Water Proofing

Removable powder coated water shield with strategically placed additional deep and ultra wide drains that have been proven for all severe environment conditions.

Frame

Ultra thick high quality aluminum alloy extruded frames serve a solid foundation for quality, longevity and a base to build superior ventilation.

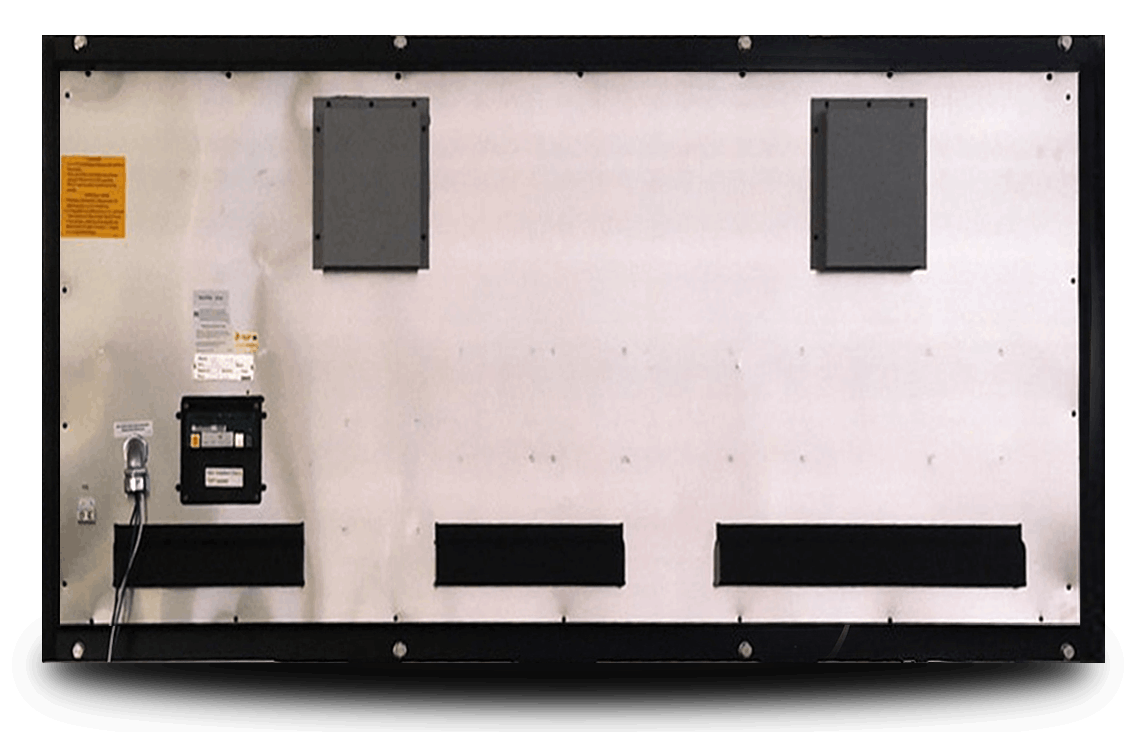

Back Panel

Optional back service access doors if needed will be free.

Control Cards/Circuit Boards

Designed in-house, made in Taiwan with stringent quality control to ensure the highest reliability.

Mounting

Standard mounting fixtures provided across the back have adjustable mounting angles.

Drivers

Enhanced Signal Drivers: Ensuring the image quality and the longevity of the display

Reinforcements

Hyoco is the only manufacturer not only providing beams and bars to reinforce the cabinetry for the extreme weather conditions, but also taking a systematic approach to the thermal ventilation design, allowing strategically designed airflow and airspeed to maintain critical parts working under desired temperature ranges for ensuring the highest reliability.

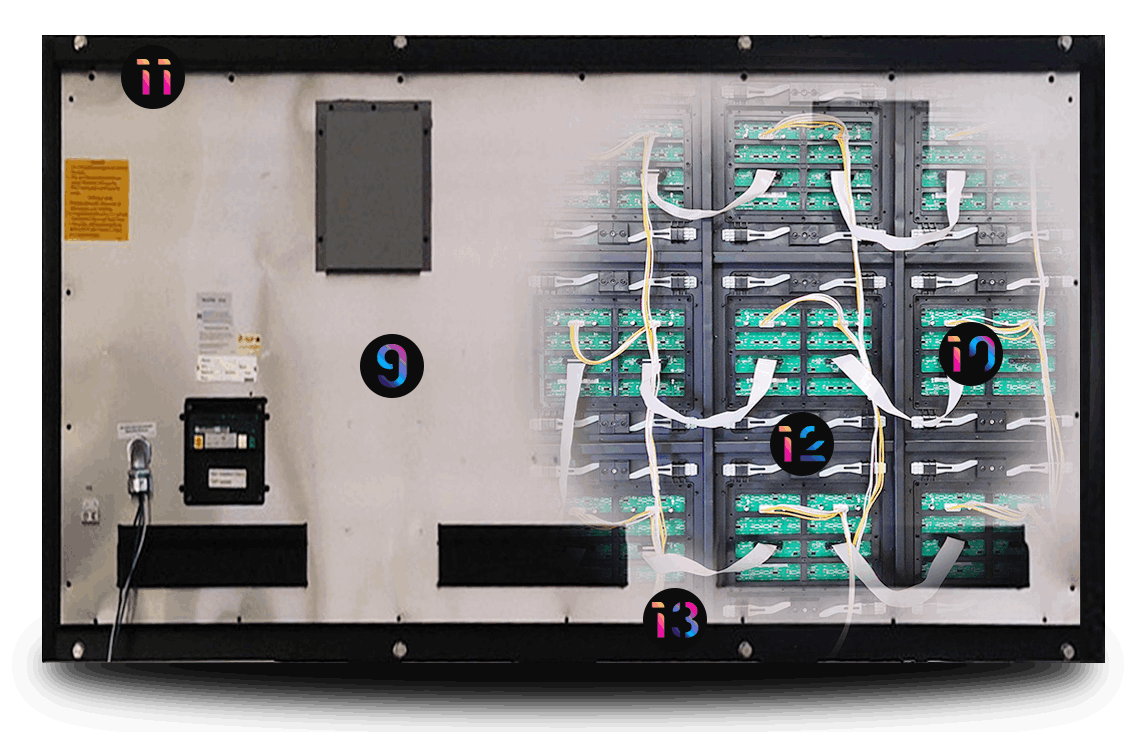

LED ANATOMY

LED Display stands out like landmark brilliantly and prominently, attracts attention with no equivalence.

Front Panel

Depending on the size of the display, 3 opening mechanism options: Sliders, Metal Cables and Gas Shocks.

Cooling

Thermostatically controlled forced air ventilation with optional heater.

Exterior

Finishing with ultra high quality powder coating material made in the America from AKZO.

Pixel/Modules

Unique display modules with Electrostatic Discharge (ESD) protection and IL technology, made from materials by General Electric (GE). Optional Hyoco Removable Pixel (HRP) modules are also available.

Power

All PCB-Emperor/Genesis Series use high grade Power Supply with Auto Protection feature specifically made for Hyoco.

LEDs

Printed Circuit Board (PCB) based Emperor Series utilize Nichia diodes that are made in Japan. While the PCB-Genesis Series uses a mixture of Nichia and Everlight LEDs.

Water Proofing

Removable powder coated water shield with strategically placed additional deep and ultra wide drains that have been proven for all severe environment conditions.

Frame

Ultra thick high quality aluminum alloy extruded frames serve a solid foundation for quality, longevity and a base to build superior ventilation.

Back Panel

Optional back service access doors if needed will be free.

Control Cards/Circuit Boards

Designed in-house, made in Taiwan with stringent quality control to ensure the highest reliability.

Mounting

Standard mounting fixtures provided across the back have adjustable mounting angles.

Drivers

Enhanced Signal Drivers: Ensuring the image quality and the longevity of the display

Reinforcements

Hyoco is the only manufacturer not only providing beams and bars to reinforce the cabinetry for the extreme weather conditions, but also taking a systematic approach to the thermal ventilation design, allowing strategically designed airflow and airspeed to maintain critical parts working under desired temperature ranges for ensuring the highest reliability.

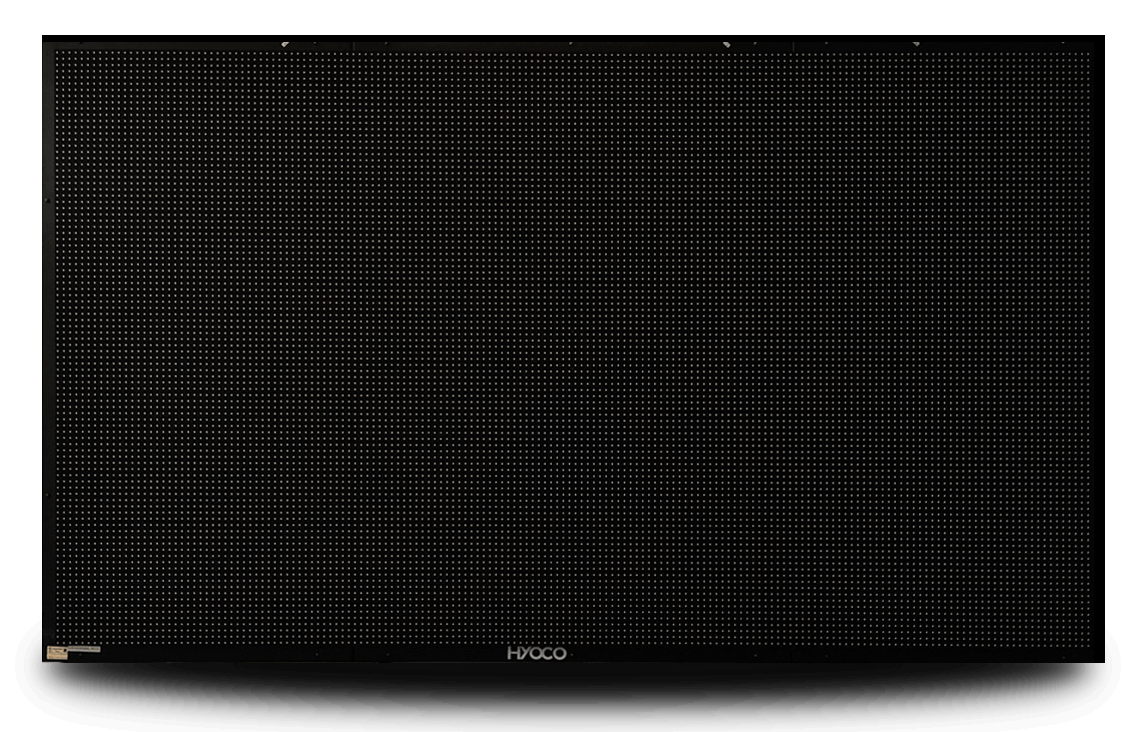

LED ANATOMY

LED Display stands out like landmark brilliantly and prominently, attracts attention with no equivalence.

Front Panel

Depending on the size of the display, 3 opening mechanism options: Sliders, Metal Cables and Gas Shocks.

Cooling

Thermostatically controlled forced air ventilation with optional heater.

Exterior

Finishing with ultra high quality powder coating material made in the America from AKZO.

Pixel/Modules

Unique display modules with Electrostatic Discharge (ESD) protection and IL technology, made from materials by General Electric (GE). Optional Hyoco Removable Pixel (HRP) modules are also available.

Power

All PCB-Emperor/Genesis Series use high grade Power Supply with Auto Protection feature specifically made for Hyoco.

LEDs

Printed Circuit Board (PCB) based Emperor Series utilize Nichia diodes that are made in Japan. While the PCB-Genesis Series uses a mixture of Nichia and Everlight LEDs.

Water Proofing

Removable powder coated water shield with strategically placed additional deep and ultra wide drains that have been proven for all severe environment conditions.

Frame

Ultra thick high quality aluminum alloy extruded frames serve a solid foundation for quality, longevity and a base to build superior ventilation.

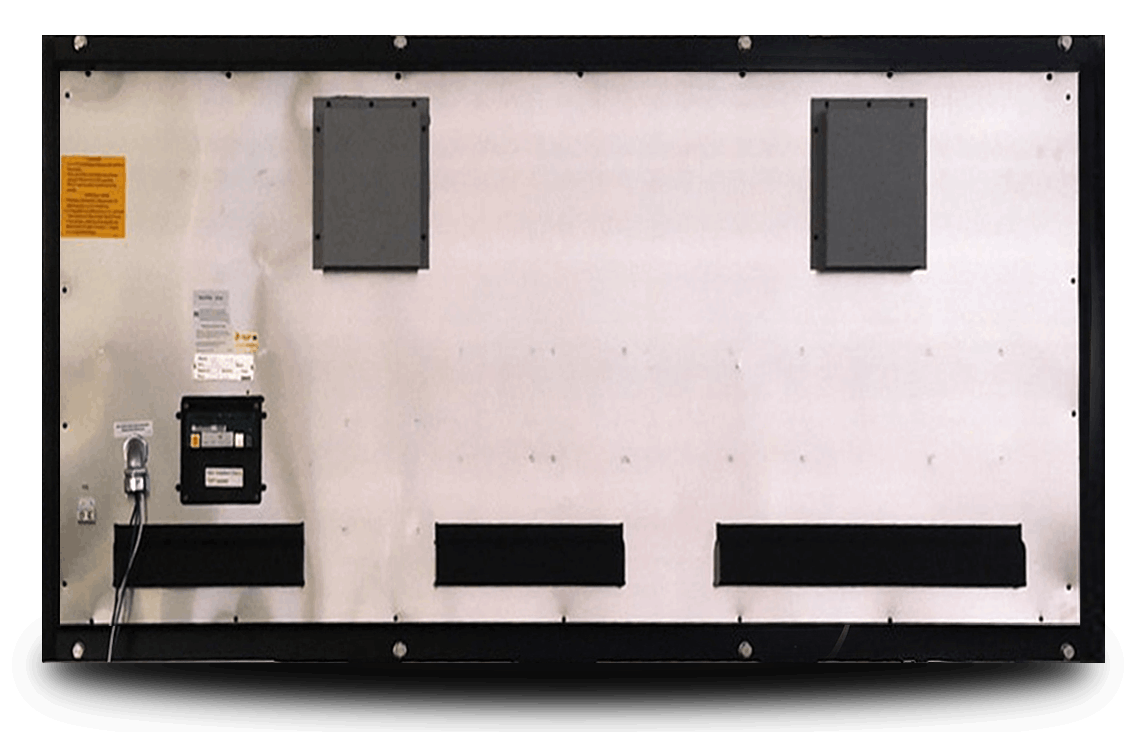

Back Panel

Optional back service access doors if needed will be free.

Control Cards/Circuit Boards

Designed in-house, made in Taiwan with stringent quality control to ensure the highest reliability.

Mounting

Standard mounting fixtures provided across the back have adjustable mounting angles.

Drivers

Enhanced Signal Drivers: Ensuring the image quality and the longevity of the display

Reinforcements

Hyoco is the only manufacturer not only providing beams and bars to reinforce the cabinetry for the extreme weather conditions, but also taking a systematic approach to the thermal ventilation design, allowing strategically designed airflow and airspeed to maintain critical parts working under desired temperature ranges for ensuring the highest reliability.